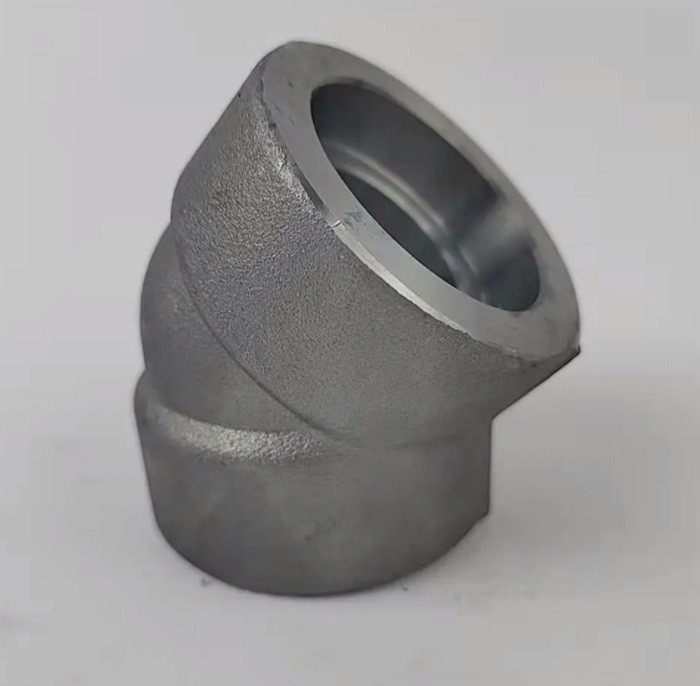

Hey there! As a forged elbow supplier, I know how crucial it is to ensure the welding quality of these fittings. In this blog, I'm gonna share some practical tips on how to check the welding quality of forged elbows. Let's dive right in!

Visual Inspection

The first step in checking the welding quality of forged elbows is a good old - fashioned visual inspection. This is like the quick once - over you give before getting into the nitty - gritty. You gotta look for obvious signs of defects.

Check for cracks on the weld surface. Cracks can be a real pain in the neck as they can lead to failure of the elbow over time. They might look like small lines or even hair - thin fractures. Also, look for porosity. Porosity shows up as small holes in the weld. These holes can weaken the weld and make it more susceptible to corrosion.

Another thing to keep an eye on is the bead shape. A proper weld bead should be smooth and have a consistent width. If the bead is too wide or too narrow in some parts, it could indicate problems with the welding process. And don't forget about undercutting. Undercutting looks like a groove along the edge of the weld. It weakens the joint and is a sign that the welding parameters might have been off.

Dimensional Inspection

After the visual check, it's time to measure things up. Dimensional inspection is super important because the forged elbow needs to fit properly in the pipeline system.

Start by measuring the outer diameter of the elbow. You can use a caliper for this. The diameter should be within the specified tolerance range. If it's too big or too small, it might not connect well with other pipes or fittings.

Next, check the wall thickness. A consistent wall thickness is key for the strength and durability of the elbow. Any significant variations in wall thickness can lead to uneven stress distribution, which is not good news. You can use ultrasonic thickness gauges to measure the wall thickness accurately.

Also, measure the angle of the elbow. For example, if it's supposed to be a 90 - degree elbow, it better be close to that. A wrong angle can cause problems in the pipeline layout and affect the flow of fluids.

Non - Destructive Testing (NDT)

Visual and dimensional inspections are great, but sometimes there are hidden issues that you can't see with the naked eye. That's where non - destructive testing comes in.

One popular NDT method is ultrasonic testing (UT). UT uses high - frequency sound waves to detect internal flaws in the weld. The sound waves travel through the material, and if there's a defect like a crack or a void, the waves will bounce back differently. A trained technician can analyze these echoes to figure out the size and location of the defect.

Another useful method is magnetic particle testing (MT). This method works on ferromagnetic materials, which most forged steel elbows are. You apply a magnetic field to the weld and then sprinkle magnetic particles on it. If there are any surface or near - surface defects, the magnetic particles will be attracted to them, making the defects visible.

Radiographic testing (RT) is also an option. It uses X - rays or gamma rays to create an image of the internal structure of the weld. This method can detect both surface and internal defects. However, it's a bit more complex and requires special safety precautions because of the radiation involved.

Destructive Testing

Sometimes, to really get a deep understanding of the weld quality, you might need to do some destructive testing. But don't worry, we only do this on a sample basis.

One common destructive test is the tensile test. In a tensile test, you take a small sample from the welded area and pull it until it breaks. By measuring the force required to break the sample and the amount of elongation, you can determine the strength and ductility of the weld.

Another test is the bend test. In a bend test, you bend the welded sample to a certain angle. If the weld cracks during the bending process, it indicates poor weld quality. This test helps to evaluate the ductility and soundness of the weld.

Material Analysis

The quality of the materials used in the forged elbow and the welding process also plays a huge role in the overall welding quality. You can use methods like spectroscopy to analyze the chemical composition of the materials.

Make sure that the base material of the forged elbow and the filler material used in welding have the right chemical composition. The wrong composition can lead to poor weldability, corrosion resistance, and mechanical properties.

Documentation and Traceability

As a forged elbow supplier, I always keep detailed documentation of the welding process and inspection results. This includes things like welding procedures, welder qualifications, inspection reports, and test results.

Documentation is important for several reasons. First, it provides evidence that the welding was done according to the required standards. Second, it allows for traceability. If there are any issues with the elbow later on, we can go back and check the records to figure out what went wrong.

Conclusion

Checking the welding quality of forged elbows is a multi - step process that involves visual inspection, dimensional inspection, non - destructive testing, destructive testing, material analysis, and proper documentation. By following these steps, we can ensure that the forged elbows we supply are of high quality and will perform well in the pipeline systems.

If you're in the market for high - quality Forged Elbow Fitting, Forged Steel Elbow, or 1 Inch Npt 45 Degree Elbow, we've got you covered. We take pride in our products and our strict quality control measures.

If you're interested in purchasing our forged elbows or have any questions about the welding quality or our products in general, feel free to reach out to us. We're always happy to have a chat and discuss your needs. Let's work together to find the perfect forged elbows for your project!

References

- Welding Handbook, American Welding Society

- ASME Boiler and Pressure Vessel Code

- API Standards for Piping Components